A Explore of Surface Mount Crystal Oscillator Performance Characteristics

What does the term surface mount crystals mean?

- Radio and television receivers, computers, and communications systems are just a few examples of the various applications used by surface mount crystal oscillators. As well as serving as frequency references, they are employed for signal timing.

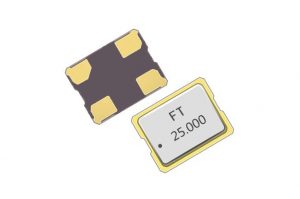

- Printed circuit boards are directly soldered with tiny, precise quartz surface mount crystals (PCB). An exact oscillation frequency is maintained by using electrical equipment like computers, radios, and mobile phones. Surface mount crystals are becoming popular in various applications and cannot be compared to through-hole crystals due to their numerous advantages. Quartz is a small, flat piece that is utilized in electrical circuits. They are commonly used when space is at a premium in high-frequency applications.

The applications for surface mount crystals:

- Many electronic manufacturers construct their goods using cutting-edge Surface Mount Crystal oscillator

- It enables them to design circuits that are more compact and effective. High-end consumer electronics like smartphones and tablets frequently employ SMD components.

- Medical gadgets and other industrial equipment also use them.

Why it is surface mount crystals so popular?

- Numerous factors contribute to its appeal. Surface mount crystals are firstly substantially smaller than through-hole crystals. Your PCB might be significantly extended as a consequence.

- Second, your project will be more reliable because this mount crystal is less likely to break during assembly. These crystals are ideal for wearable, IoT, and many other applications because of their exceptional reliability and long-term stability.

- Since they are thinner and smaller than traditional crystals, they are more suited for compact electronics. They are also easier to assemble and need less lead time to make.

- These mount crystals are more resistant to vibration and stress. The final product’s stability is dependent on its stability.

The specifications of the Surface mount crystal oscillator:

- The exact frequency regardless of temperature or driving intensity.

- For all models, the frequency range (6-156.25MHz)

- Reliable precision, superior shock performance and diminutive size.

Instructions for understanding surface mount crystal effects:

- The term surface-mounted device (SMD) is used. Instead of being placed via a hole, a component has been soldered to the circuit board.

- Surface mount manufacturing has transformed the electronics sector over the past few decades and is still one of the most crucial processes in manufacturing contemporary electronics. Consumer goods frequently employ this technology.

- SMD components often have a smaller physical footprint and lower electrical resistance than through-hole components. Faster assembly times and better manufacturing rates are made possible by SMD technology.

- Due to the lack of drilling holes or component insertion, this method minimizes the amount of PCB area required and is more affordable. Resistors, capacitors, inductors, diodes, transistors, ICs, and other electrical components can be mounted on printed circuit boards using SMT technology (PCBs).

Expanding a warm air joining station, how should you join SMD modules?

The procedure of soldering is relatively simple. Warm up the surface, apply some flux, and then solder. SMD component soldering, however, needs a little skill and a few materials and tools. Electronic PCB assemblies now employ surface-mount components (SMT). Some SMT components can be soldered using a regular soldering iron.

- However, they cannot use it to solder parts with terminations on the underside. Soldering components with tiny, closely spaced leads may be complex with a soldering iron.

- The procedure is accelerated by hot-air soldering, producing solid solder joints without leaving solder bridges on the leads.

- The basic process must expose the solder junction, the component, and the PCB to sufficiently hot air. Depending on the current amount of resources and the kind of solder being used, different hot air temperatures and flow rates will be required.

- The warm-air soldering placement wand is then precisely positioned on top of the section, and the component is firmly set on the solder lines. Heated air is applied until the solder melts and binds to the component’s leads. Deficient heat and time will result in an unkind solder bond, while too much heat and time can damage a part and the PCB.

- Adjusting the temperature will guarantee that the solder dissolves, lacking harmful to the element or the electrical circuit board.

- To get the desired result, it may be required to alter the three variables of temperature, air velocity, and time. Using the correct method and the appropriate equipment and materials will yield high-quality solder connections. The technique is a taught process that is enhanced with repetition.

- A hot-air joining position may join surface-mount mechanisms, providing vital solder junctions, saving time, and lowering the possibility of harming the component or the circuit board.

- The join packs on the circuit board must have an adequate quantity of melted and hardened join before connecting the component. Additional flux is required for the proper solder connection to develop and for the element to remain in place when hot air is provided. Paste flux is the most often used form because it is easier to use and produces a sticky surface that prevents the component from moving accidentally.

- Likewise, the airflow volume needs to be as high as it is possible to make it without interfering with other SMT parts. Using an outlet with the right size and form will lessen the belongings on adjoining components. Most hot-air soldering stations are compatible with various nozzles from Circuit Specialists.

Conclusion:

ChipSun may meet your demands for a surface mount Crystal oscillator. Manufacturers utilize this crystal assembly method to mount components on circuit boards. Compared to through-hole crystals, they are more compact and have a smaller profile. Please don’t be afraid to call or email us to let us know what you need. We can provide comprehensive certification and reliability assurance processing for the most demanding demands because of our electrical testing skills. Since its founding, the company has always sought to increase the value of its customers by offering a full range of solutions for various frequency control components, components, and modular design requirements to satisfy all of their needs. ChipSun Technology has consistently surpassed customers’ expectations regarding price, quality, delivery, and other factors.